When installing a Vapormatic Short Motor you can be confident that your rebuild will come in on time, on budget and add value to your tractor.

What's included?

All blocks are supplied fully assembled including:

*Next day delivery is subject to availability and delivery charges. Please see your Stockist for more information...

In any rebuild it is important to ensure that all engine auxiliary parts are in good working condition. It is recommended that checks and replacements are made where necessary on parts such as, water pumps, thermostats, clutches, silencers, injector nozzles, fan belts, filters and radiator hoses.

Visit www.vapormatic.com to find the parts you need.

Short Motors suitable for: Perkins A3.152 Rope seal replacement suitable for: Massey Ferguson 35, 35X ➡ Part no. VPB8017

Short Motors suitable for: Perkins AD3.152 Rope seal replacement suitable for: Massey Ferguson135 ➡ Part no. VPB8018

Short Motors suitable for: Perkins A3.152 Lip seal replacement 5 Ring piston replacement suitable for: Massey Ferguson 135, 230, 240, 250, 340 ➡ Part no. VPB8019

Short Motors suitable for: Perkins A3.152 Lip seal replacement 4 Ring piston replacement suitable for: Massey Ferguson 148, 350, 550 ➡ Part no. VPB8020

For a complete list of supporting parts available for these short motors, please visit: www.vapormatic.com

Short Motors suitable for: Perkins A4.236 Rope seal replacement suitable for: Massey Ferguson 168, 175 plus many more industrial and agricultural applications. ➡ Part no. VPB8027

Short Motors suitable for: Perkins A4.248 Rope seal replacement suitable for: Massey Ferguson 178,185,188 plus many more industrial and agricultural applications ➡ Part no. VPB8028

Short Motors suitable for: Perkins A4.236 Lip seal replacement suitable for: Massey Ferguson 168, 175, 265, 275, 565, 575, 675, 365, 375 plus many more industrial and agricultural applications ➡ Part no. VPB8029

Short Motors suitable for: Perkins A4.248 Lip seal replacement suitable for: Massey Ferguson 178, 185, 188, 285, 290, 590, 690, 390 plus many more industrial and agricultural applications ➡ Part no. VPB8030

Note: When installing these short motors the following products are also needed: Top gasket set Part no. VPA4006 (without fire ring liners), Bottom gasket set Part no. VPC6007, Cylinder head bolt kit Part no. VPA3920 (if it is a replacement for a MF 300 series or later tractor, then you will not need this kit)

Short Motors suitable for: FORD BSD333 - Normally Aspirated

Direct replacement for: BSD333: 4000, 4600, 4610, 4630

Also suitable replacement for: 2000, 3000, 2600, 3600, 3055, 3900, 4100, 2310, 2610, 2810, 2910, 3610, 3910, 4110 ➡ Part no. VPB8024

Earlier specification engines with 1/2" UNC thread cylinder head bolts will also require VPA3919 cylinder head bolt kit, VPA5083 timing cover kit bolt kit, VPA5080 timing hub bolt, VPA5081 timing hub and VPC5440 rear main seal housing to complete installation of the New Short Motor.

For a complete list of supporting parts available for these short motors, please visit: www.vapormatic.com

Short Motors suitable for: Ford BSD444 - Normally Aspirated

4 Cylinder, 111mm bore x 111mm stroke Suitable for: Ford 6410, 6600, 6610, 6700 ➡ Part no. VPB8025

Also suitable replacement for: BSD442T Suitable for: Ford 7600, 7700 ➡ Part no. VPB8026

Note: When installing these short motors the following products are also needed: Oil pump Part no. VPD1100, Oil pump driveshaft Part no. VPD1502 Top gasket set Head gasket Part no. VPA4103, Head gasket Part no. VPA4303, Bottom gasket set ➡ Part no. VPC6106.

For a complete list of supporting parts available for these short motors, please visit: www.vapormatic.com

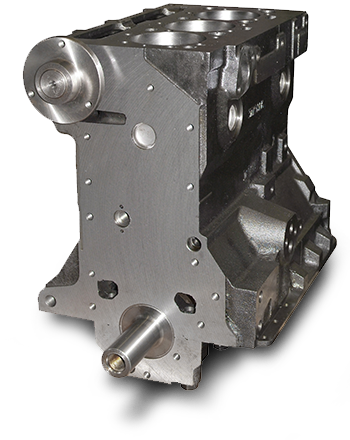

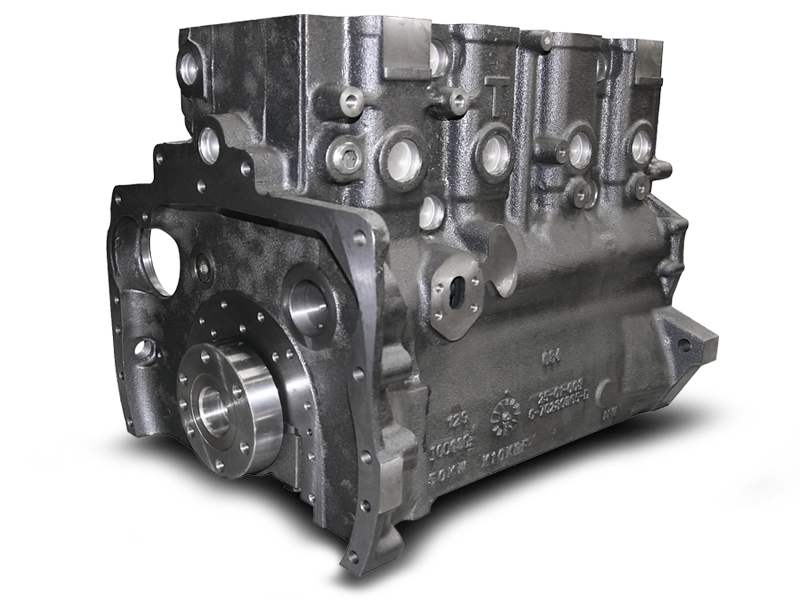

The all new block is manufactured exclusively for Vapormatic, using the very latest "lost-foam" casting technique. 21st century foundry processes and the metallurgical specification deliver a high degree of accuracy and an excellent surface finish, both internally and externally.

The latest CNC machining and coordinate inspection has enabled ISO9000 repeatable dimensional, geometric and positional control. The Short Motors are built in Exeter, U.K. by our engineers who ensure all critical measurements are checked at every stage of the build process.

Vapormatic Short Motors only use new parts and are fully supported by our 12 months parts and labour warranty.

For a complete list of supporting parts available for these short motors, please visit: www.vapormatic.com

Camshaft followers inserted and checked to ensure free movement within machined housing / Camshaft installed and free rotation checked / Oil pump drive gear mounted and backlash checked / Crankshaft Assembly and Checks

Care taken to ensure oil transfer holes are aligned - bearings to block / Crankshaft installed and free rotation checked / Final torque sequence carried out using calibrated equipment / Crankshaft end float checked to ensure it is within tolerances

Measurement checked from the bore to the side of the thrust face of each piston / Checks carried out in multiple places within the bore / Reduces oil consumption and noise

Piston rings checked to ensure they are within tolerance / Checks made in multiple places within the bore / Aids compression, fast starting and reduced emissions

Piston and connecting rod assembly checked to ensure free rotation of the piston pin / Piston rings checked and staggered around piston to avoid excess oil consumption, aid compression and reduce blow-by

Piston protrusion is checked to ensure the correct compression height is achieved / Maximised compression and aid starting

All torque settings are checked / Final rotation ensure no tight spots are experienced / Final visual inspection carried out / Rust inhibitor applied to all surfaces

Sealed in a plastic bag with silica gel absorbent pack / Secure tri-wall box to eliminate movement in transport